Medical Device Manufacturing in India is undergoing a massive transformation. With digitalization penetrating multiple practices from Medical testing to Surgical procedures, Healthcare is undergoing a successive evolutionary phase. As Medical Device Developers we have a crucial role to play in translating technology to make affordable medical devices that promote quality healthcare and enable democratized healthcare ecosystem.

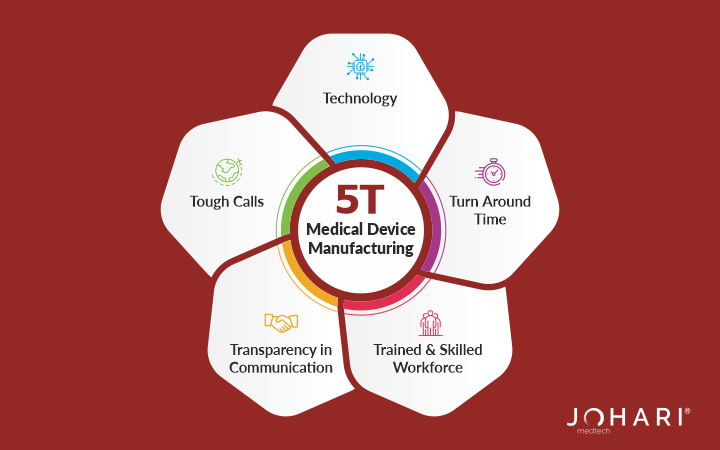

5 T’s formula for Quality Medical Device Manufacturing

1. Technology

- Continual research of the best technologies in the domain to develop devices that are accessible, affordable, and at par with global standards

- Incorporate the latest trends like AI, ML, and IoT to enable automation in manufacturing processes to deliver quality results with minimum overhead costs, delays, and errors

- Collaboration with academia to accelerate commercialization of the Medical Device concepts under research in these institutions

2. Turnaround Time

- Maintain a strong bench of vendors and efficient supply chain to fast track projects at an optimized cost

- Pre-planning and efficient project management at different levels and phases of manufacturing

3. Transparency in Communication

Communication is the key to every successful client-manufacturer relationship. All the changes and modifications must be communicated effectively to the client. Communicating changes & modifications throughout the product development cycle avoids ambiguities and conflicts at the end

4. Trained & skilled workforce

Manufacturing is all about accuracy, precision, and quality of the device. A professionally trained team at different levels of production is necessary to deliver a quality project within the stipulated timelines. A minor unnoticed glitch at any stage can amplify the error and make things complex to handle. Certified manufacturing organizations must conduct regular training to ensure the team is in sync with the latest updates in industry

5. Tough Calls

Often manufacturers have to take tough calls for the client’s benefit. For instance, they may have to let go of some very long-held vendors or they have to take a certain level of risk while balancing cost and innovation. But, it’s all worth it once a quality Medical Device is delivered

Sign up with Johari to Explore Seamless Medical Device Manufacturing

As a 40+ years MDSAP, US FDA, and ISO: 13485 certified manufacturing unit in Medical Devices, we comply with 5 T’s Rule of Medical Device Manufacturing to deliver quality medical device projects.

Schedule your consultation today to explore complete Medical Device Manufacturing with Johari Digital Healthcare Ltd.!