MDSAP & FDA Certified Medical Device Manufacturing Company

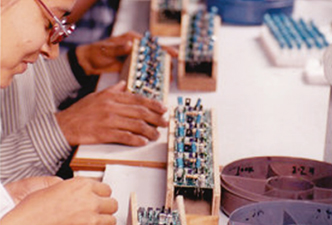

Syrma Johari MedTech is the leading electronic medical device manufacturer catering to global clients. We design, develop, engineer, and manufacture medical devices for global markets. We are MDSAP, US FDA, and GMP audited electronic medical device manufacturing company in India.

We operate from a 10,00,000 square foot, state-of-art medical device manufacturing facilities in India. Johari innovates through its R&D and Design Center in Europe and India. Our services accelerate medical device development and optimize manufacturing costs. Johari’s versatile product development and manufacturing portfolio includes innovative pain management, medical aesthetics, diagnostics, critical care, patient monitoring and surgical devices.

Manufacturing Locations

State-of-the-art Design Centers

%

Export Business

%

Client engagements based on long term partnerships

Making lives better through MedTech solutions

At Johari Medtech, we ensure innovation-led quality manufacturing at optimal cost with regulatory support,

supply chain assistance, and precision across every step of the process.

Vision

Exponential growth through partnerships with world’s leading MedTech companies.

Mission

We Pursue zero side effects to body, zero effect to environment, zero defects in quality, inspired by natural science, improved by technology.

Core Values

Authenticity: We believe in being genuine and transparent to our stakeholders.

Extra Step: We believe in taking an extra mile to innovate and succeed.

Customer & Vendor Delight: Flight needs two wings: Delight of customers & Satisfaction of vendors.

Respect: We believe in treating everyone with respect and courtesy.

Quality: We believe in the best quality, best technology and the best product.

Beyond Manufacturing

Design for Manufacturing

Our Design for Manufacturing (DFM) approach focuses on developing high-quality, cost-effective products optimized for production. By addressing manufacturability early in the design process, we minimize costly design revisions and delays. Through careful material selection, efficient assembly, and streamlined production methods, we ensure a smooth transition to market-ready products.

New Product Introduction

When launching a new medical device, time-to-market and quality are critical. Our integrated New Product Introduction (NPI) process bridges the crucial phases of design and manufacturing, ensuring seamless production. Through close cross-functional collaboration across design, engineering, production, and QARA teams, we meticulously plan, execute, and optimize your product for efficiency, compliance, and quality, thereby accelerating your go-to-market timeline.

Reliability Engineering

Our reliability engineers use established engineering techniques to predict and meet reliability goals, ensuring consistent performance of your medical device even under demanding conditions. Through rigorous testing and analysis, we identify potential failures and their root causes, implement measures to prevent and mitigate failures, validate product performance under accelerated conditions, and assess useful life for long-term durability.

Certifications

MDSAP, ISO 13485:2016, US FDA Certified cGMP & 510(k) Certifications

Johari MedTech is a leading medical equipment manufacturer with 40+ years of excellence. The manufacturing facility complies with MDSAP, ISO 13485:2016, and FDA (21 CFR 820) standards and processes. We also take special care to protect your intellectual property at every step of the way by following stringent documentation process to maintain credibility.

Product Safety & EMI/EMC

Through our Compliance Group we can guide your product to comply with requirements listed under EMI / EMC & Product Safety Standards. Whether the project is at an early design concept stage, prototyping or manufacturing stage, we readily analyze, test and assist with any required design or component level changes.

Manufacturing Site Inspection

We operate from a 10,00,000 square foot ISO: 13485:2016 compliant manufacturing facility. Regular audits by MDSAP and various global authorities confirm our quality and standards. We also perform GAP analysis & process mapping to continuously evolve our manufacturing services as per changing regulations and standards of quality.

|

|

|

|

|

Technical Construction Files

We help our clients in completing documentation requirements related to:

- Technical Write Ups (Instructional Manual, Operator’s Manual etc)

- Product Construction Details

- Engineering information (BOM, Schematics, Cad Drawings, PCB Layouts, Assembly Instructions)

- Software Validation Records

- Device verification Records

- Device validation: This is normally done through the Substantial Equivalence document or by referring to earlier proven clinical studies

Board Members

Satyendra Johari

CHAIRMAN

Nisha Johari

MANAGING DIRECTOR

J S Gujral

NON-EXECUTIVE DIRECTOR

Jayesh Nagindas Doshi

NON-EXECUTIVE DIRECTOR

Ashutosh Maheshvari

INDEPENDENT DIRECTOR

Leadership Team

Suhas Tamras

Chief Executive Officer

Tejas Shah

Head – Business Development

Dusan Todovic

Head- Technology

Dilkash Mohammed

Head- Technical BD

Preetesh Bhandari

Head- Operations

Ravindra Peerannawar

Head – Design

Sabyasachi Nath

Head – QARA

Monali Bhansali

Head- Strategy & Marketing

Dhanesh Jangid

Head- Finance

How it all began?

The company started with hearing aid production in a 500 sq. ft garage. In 1978, Johari became one of the top three companies in India to produce hearing aids. In 1987 the operations moved to a larger 7200 sq ft manufacturing facility & soon in 1989 Johari became one of the pioneer players to receive US FDA 510k clearance for electrotherapy devices.

As the work and demand for Johari products/services grew, the facility shifted to a 45000 sq. ft manufacturing facility & succeeded in getting ISO 13485 GMP audit in 2005. In a bigger space production boosted and processes became more robust and agile in meeting deadlines, innovating, and grabbing global clients.

In 2019 Johari Medtech was honored with India SME 100 awards. Being a firm dedicated to healthcare device manufacturing Johari aims to become a significant contributor in the mission of making India self-sufficient in healthcare.

In 2021, observing a steady growing demand of global business in MedTech, Johari Digital expanded its facility, adding a sprawling 20,000 sq ft Design & Engineering center. With the expansion, Johari is well-positioned to handle increasing projects in multiple domains of healthcare including life science products, diagnostic devices, and therapeutic devices.

Company Timeline

Our inspiring journey is indeed a chronology of proud accomplishments. While every day was a new accomplishment for us, sharing few prominent milestones conquered along the way.